Table Top Model Descriptions:

Purpose:

The TimberFish Technology is a new form of Ecologically Integrated Agriculture that can mitigate Climate Change by using green and dead wood from sustainably managed forests to locally produce contaminant free seafood, renewable energy, and clean water. The technology is scalable and works equally well at the table top level, or at a level that can produce a million pounds of seafood per year. The Table Top Model provides a way for everyone to understand this technology by actually operating a working system in their home, or classroom, or virtually any other locally available space in their neighborhood or community. The interaction with the Model will generate an understanding of ecological thinking and how that can lead to resolving Climate Change and other environmental problems.

These are aquaculture systems and can be used for fresh water or salt water organisms, which can vary to include warm or cold water species depending on your local environment or interests. Fish will be the most commonly grown organisms but a variety of mollusks (snails, clams, etc.) and crustaceans (shrimp, crayfish, etc.) can also be grown.

It is important to remember that when working with ecosystems in these Table Top Models the ecological processes always function. They may not give you the “experimental” result or demonstration that you expected, but that just means that you were not doing the experiment or demonstration that you thought you were doing. Putting wood chips and nutrients and water together will result in microbial growth. They are everywhere. Putting a little dirt from around a tree in the mix will speed things up. Adding small samples from local ponds, streams, ditches, puddles, muds, etc., will speed it up even more.

These ecosystems with an aquarium and three or four ecoreactors can be set up in a variety of configurations and can be operated to achieve the following objectives.

Objectives:

- Show that fish and macroinvertebrates such as shrimp, snails, clams, etc., can live and grow in an environment that contains only wood chips and nutrients without any other food source.

- Identify various microorganisms and smaller invertebrates that adapt to, and thrive within, the system, and which serve as a food source for fish and macroinvertebrates.

- Quantitate the production process by measuring input variables and obtained outputs, and calculating how many pounds of fish or macroinvertebrates can be produced from a given weight of wood and given weights of nitrogen and phosphorus supplied as nutrients.

- Optimize the production process by studying a wide range of process variables. These can include;

- Various species of fish and macroinvertebrates.

- the quantities and qualities of wood and nutrients provided,

- the configuration of the various zones, recycle flows, and pumping and aeration rates,

- water quality parameters such as pH, temperature, salinity, dissolved oxygen levels, nitrogen and phosphorus concentrations, alkalinity, micronutrients, etc.

Accessories that would be required to meet each of the objectives:

- Water testing kit to measure pH, ammonia, and orthophosphate. Chemical solutions to provide acid and alkaline buffers, and input ammonia, orthophosphate, and other required micronutrients.

- Sampling equipment. Some sort of magnification device which can range from a simply magnifying glass to various levels of microscopes. These could include; a general purpose microscope to dissecting microscopes for small invertebrates, and phase contrast microscopes for bacteria.

- Measuring equipment to accurately quantify volumes of liquid solutions applied to various scales to weigh wood chips used and product animals harvested. Drying oven. Water testing kit needs to include salinity, total dissolved solids, suspended solids, alkalinity.

- Water testing kit needs to include Dissolved Oxygen and ORP (Oxygen Reduction Potential). Accurate flow measuring for recycle and aeration. Some lab analysis for COD (Chemical Oxygen Demand), TKN (Total Kjeldahl Nitrogen), and Total Phosphorus. Muffle furnace for Total Solids determination.

Various levels of glassware will be required for each level as well as thermometers (and heaters if you want to grow warm water fish).

The Table Top Model provides an accurate representation of the fundamental principles that underlie large scale applications of the TimberFish Technology that can produce millions of pounds of fish per year. The strength of this system is based in its large and diversified microbial biomass. This exists in a variety of forms as fixed films on wood chips or other forms of plant material, and suspended forms comprising single cells or filamentous or globular aggregates which can occur at a wide range of concentrations. This explains why there are three types of woodchip baskets and multiple water zones which can have high levels of suspended solids or qualify for tertiary treatment water quality standards. An additional principle focuses on the close proximity that fish will have to the natural foods that they eat, whether that is a microbial floc or a variety of invertebrate organisms. These can fall out of perched irrigated chip baskets or be available to the fish which swim around the wood sticks or chip baskets in some configurations. If harvesting of invertebrates or floc is required it can occur next to the fish tanks and hence not require processing, packaging, or shipping expenses.

How to set up a TimberFish table top unit

The following discussion will present different descriptions for setting up a 10 gallon and a 20 gallon Table Top Unit.

For either Table Top project it is helpful if you have an extra 10 gallon conventional fish tank set up to raise the fish used in the project (Guppies are good for this). This will serve as a control and facilitate comparison with standard fish raising systems. The TimberFish system is an ecosystem and as such will contain many different types and numbers of living organisms. You will need to know, or learn, who they are, what they require, what they like, how they reproduce, how they interact with each other, and how they interact with you. Since the apex or product animal in this ecosystem is fish you should know and be familiar with how to raise then conventionally.

Here is a description of setting up a 10 gallon unit.

|  | | |

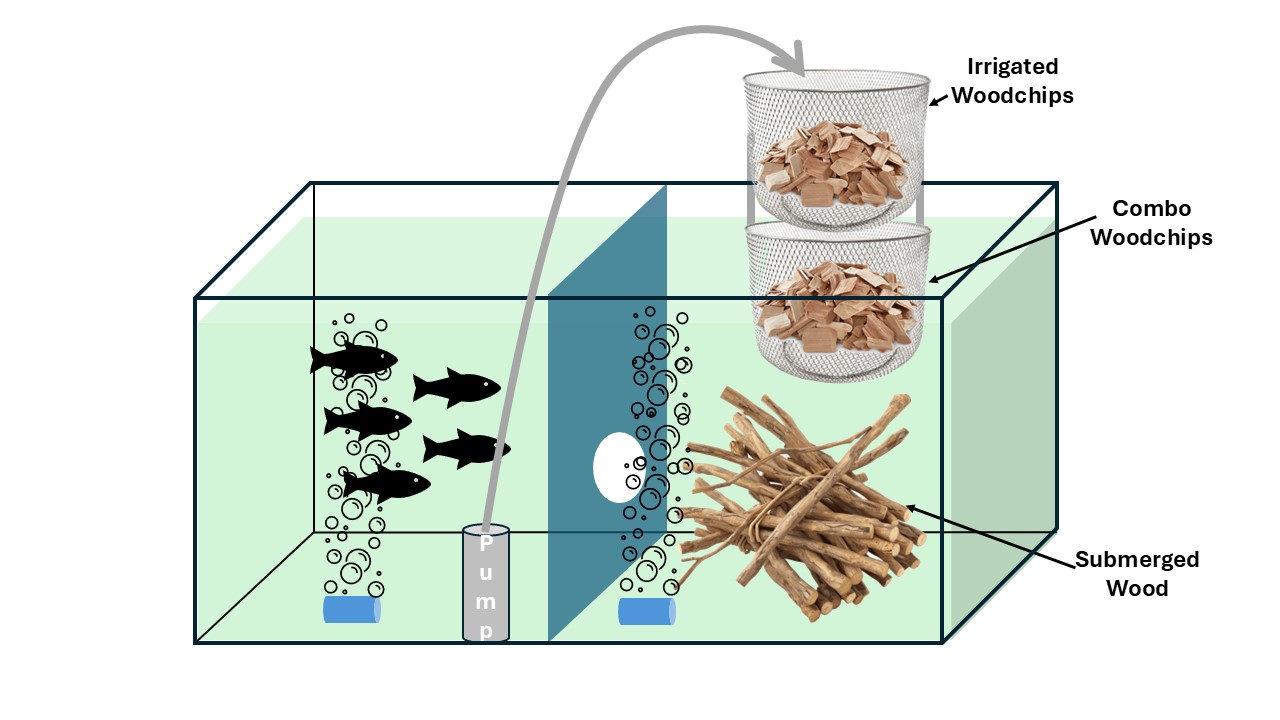

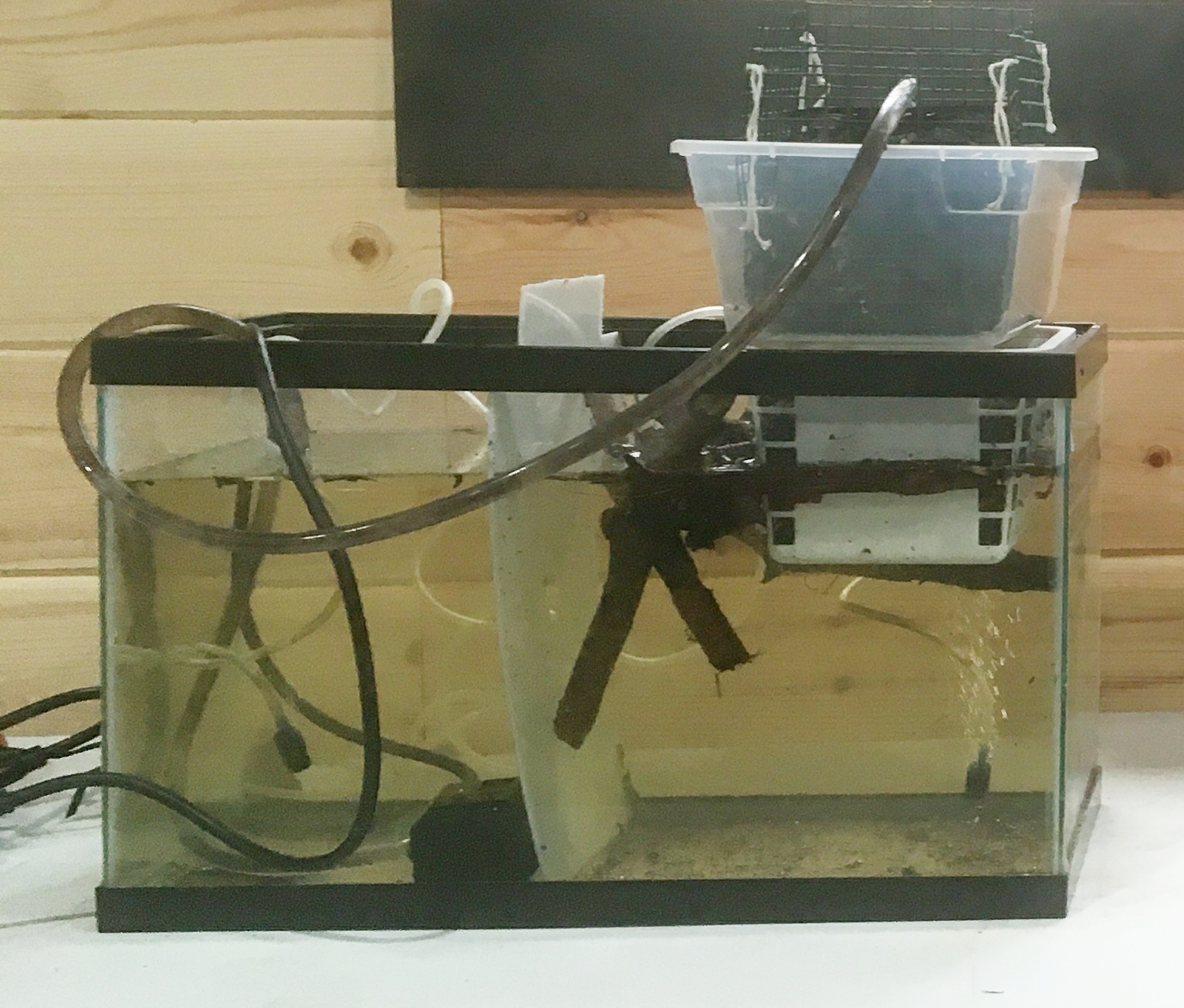

Here is a diagram of this version that was created by Leland Beaumont and a photo of an operating version of this unit. This is a system you can build yourself. In the version shown above we used a 10 gallon aquarium, a food storage container, a dryer vent screen, some hardware cloth, small tubing, and aquarium recycle pumps and aerators.

It turns out that the process of building the diagram is sort of like the process of building the model. So here are some additional photos that show how the model was constructed. This is followed by a series of diagrams that Leland Beaumont created that also show the evolution of the construction of the model, as well as an additional possible configuration.

The project tank can be any ten or more gallon fish tank. You will need a divider that can separate the aquarium into fish zones and wood zones. This can be a sheet of plastic, screen, glass, or other similar material, that you can construct with a hole to act as a passageway for the fish to swim from one zone to the next and back. In some configurations this can be covered with a removable screen so that the operator can control fish access to the wood zone. In this example a plastic sheet is cut to fit the sides of the tank and in which a one to two inch hole is cut to allow fish and water passage between zones.

The system will comprise two types of baskets to hold wood chips. One of these, the perched chip basket, will hold wood chips that are irrigated with water but never submerged. The second, the combo basket, will hold chips, some of which will be submerged while others will be above the water line and hence just irrigated.

The woodchips will stay in each basket, or the tank, until it has degraded to the point where it needs to be removed and replaced. Woodchips will be in the Irrigated and Combo baskets, but the wood in the tank itself will be sticks and branches. These will be placed vertically so that the fish can swim around them and feed on the floc or organisms that attach themselves to the sticks or settle to the bottom of the tank.

These baskets can be constructed from hardware cloth or other screens that have holes or opening from about one quarter to one half inch (one centimeter) to allow water, biomass, and small animals to pass but will retain the wood chips. These can also be made by drilling holes in plastic containers, by using food colanders, or other plastic objects.

In the shown example the top perched chip basket is made of hardware cloth and it is placed in a plastic food container with holes drilled in the bottom. This is just to allow the chip basket to be easily supported above the aquarium. The combo basket in this case is a plastic vent screen from a clothes dryer that is intended to keep small animals from entering your clothes dryer or house.

The Combo basket will be placed so that half of the chips will be above the waterline and half will be below the waterline. The Irrigated basket will be separated from the Combo basket by an air zone, but will have "feet" or some sidewall extension so that there is a wet direct connection between the two baskets. This will allow snails to travel from the bottom of the tank to the top of the Irrigated basket and back if they so desire, and they will.

Examples of organisms that populate each zone will include small earthworms for the Irrigated basket, Oligochaetes (a small diameter aquatic worm) in the Combo basket, and Gammarus (an aquatic fairy shrimp or scud) for the tank zone. Freshwater snails will inhabit all three zones. There will be a myriad of other invertebrates that will appear but these will be among the bigger ones that can be easily seen by the observer.

The system will also need an air pump with two outlet nozzles for air tubing (or one nozzle with a stream splitter). This will allow two air lines going to two aeration stones. One of these will be in the fish zone and the other will be in the wood zone.

The system will also need a recycle pump to transfer water from the bottom of the fish zone to the top of the perched wood chip basket. The recycle pump needs a flow controller valve or one can be put in the recycle line.

You will also need a five gallon pail and a siphon for tank cleaning when needed. When you set up the system you want to put the perched chip basket above the combo basket. The combo basket will be in the top of the wood zone in the aquarium and located so that part of the chips are submerged and part of the chips are on top of the submerged chips but still above the water line. If necessary, connecting sticks should be installed so that a small snail could easily go from the top of the perched chip basket to the bottom of the wood chip zone and back. In the rest of the aquarium wood zone small sticks should be placed so that fish can swim around them and feed on the floc and microorganisms that will grow and collect on surfaces in the wood zone.

20 Gallon Unit:

Here is a description of setting up a 20 gallon unit.

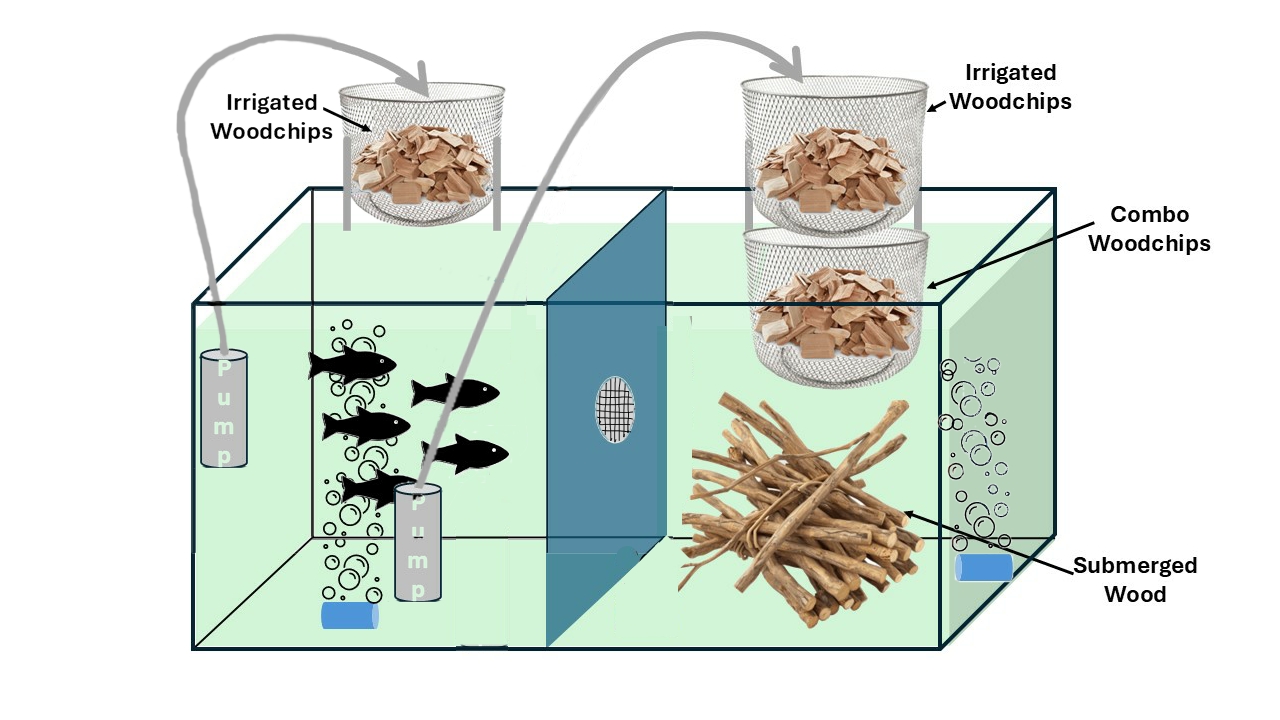

This Table Top Model includes a 20 gallon aquarium and four ecoreactors.

Here is a conceptualized diagram of such a unit and a photo of a 20 gallon tank with four ecoreactors.

Δ Δ |  Δ Δ |

Additional Photos and Descriptions

The project tank can be any 20 or more gallon fish tank. You will need a divider that can separate the aquarium into fish zones and wood zones. This can be a sheet of plastic, screen, glass, or other similar material, that you can construct with a hole to act as a passageway for the fish to swim from one zone to the next and back. In the diagramed example a plastic sheet is cut to fit the sides of the tank and in which a one to two inch hole is cut to allow fish and water passage between zones.

The system will comprise several types of baskets to hold wood chips. Two of these, the perched chip baskets, will hold wood chips that are irrigated with water but never submerged. These are identified as Ecoreactors E3 and E4 in the Additional Photos and Descriptions referenced above.

A third basket, the combo basket identified as Ecoreactor 2 (E2) in the referenced document, will hold chips, some of which will be submerged while others will be above the water line and hence just irrigated.

These baskets can be constructed from hardware cloth or other screens that have holes or opening from about one quarter to one half inch (one centimeter) to allow water, biomass, and small animals to pass but will retain the wood chips. These can also be made by drilling holes in plastic containers, by using food colanders, or other plastic objects.

In the photographed example Ecoreactors 2, 3, and 4 are made of a plastic hardware cloth. E3 and E4 are supported above the tank while E2 will be placed so that some of the chips will be above the waterline and others will be below the waterline. The Irrigated baskets, E3 or E4, will be separated from E2, the Combo basket, by an air zone, but will have "feet" or some sidewall extension so that there is a wet direct connection between the two baskets. This will allow snails to travel from the bottom of the tank to the top of the Irrigated basket and back if they so desire, and they will.

At the bottom of the wood zone there will be a stick structured ecoreactor, E1. This is a coated fence type wire mesh with 2 by 3 inch holes that support sticks in a vertical position. This will allow fish to freely swim around the sticks and eat any microbial floc or invertebrate organisms attached to the sticks.

Examples of organisms that populate each ecoreactor will include small earthworms for the Irrigated baskets E3 and E4, Oligochaetes (a small diameter aquatic worm) in the E2 basket, and Gammarus (an aquatic fairy shrimp or scud) for the tank zone. Freshwater snails will inhabit all four ecoreactor zones. There will be a myriad of other invertebrates that will appear but these will be among the bigger ones that can be easily seen by the observer.

The system will also need an air pump with two outlet nozzles for air tubing (or one nozzle with a stream splitter). This will allow two air lines going to two aeration stones. One of these will be in the fish zone and the other will be in the wood zone.

The system will also need two or three recycle pumps to transfer water from various locations in the tank to the top of the perched wood chip baskets E3 and E4. These recycle pumps need flow controllers or controllable valves located in the recycle lines. Additionally you will also need a five gallon pail and a siphon apparatus for collecting solids from the bottom of the fish zone when needed. These solids will be returned to the top of E3 or E4, whichever one is located above E2 in the wood zone.

When you set up the system you want to put the E4 perched chip basket above the E2 combo basket. E2 will be in the top of the wood zone in the aquarium and located so that part of the chips are submerged and part of the chips are on top of the submerged chips but still above the water line. Connecting sticks in E1 should be installed so that a small snail could easily go from the top of the perched chip basket E4, to the bottom of E1 in the wood chip zone and back.

Start Up

As stated earlier, for either Table Top project it is helpful if you have an extra 10 gallon conventional fish tank set up to raise the fish used in the project (Guppies are good for this). This will serve as a control and facilitate comparison with standard fish raising systems. The TimberFish system is an ecosystem and as such will contain many different types and numbers of living organisms. You will need to know, or learn, who they are, what they require, what they like, how they reproduce, how they interact with each other, and how they interact with you. Since the apex or product animal in this ecosystem is fish you should know and be familiar with how to raise then conventionally.

Set up the conventional aquarium and start growing the organisms you will use in the experiment. Your water source is important for your project. If you will use a municipal water source you will need to make sure it is dechlorinated. You can do this by letting it stand in an open pail for a day before adding it to your system.

Once the control aquarium is set up and running add about 10 gallons of water (dechlorinated if you are going to use a municipal water source) to the 20 gallon experimental tank. Then take a five gallon pail and go to a small local pond or stream. Collect five gallons of water and put that in your experimental tank.

Then return to the pond or stream and collect a variety of samples of muck, sediment, aquatic vegetation, and dead plant material that is in and associated with the water source. Look for and collect any small organisms you can find that are living in the pond or stream. In particular these should include any larger invertebrates such as aquatic worms and snails. A magnifying glass can be helpful here. Put all your samples in another five gallons of water. Bring the sample pail back and aerate it for a day or two. Allow it to stabilize to your room temperature and then stop aeration and let the solids settle to the bottom of the pail. Decant it into your experimental tank in the wood zone side. Examine the settled solids and if you can see any organism activity try to collect that and add it and some of the solids to the experimental tank wood zone as well. Activate all aeration and recirculation flows but do not add fish yet.

Operation

Once your system has run for a week or more you can add fish or other product animals from your conventional fish tank. You need to add fresh water daily to prevent salinity buildup. So for a 20 gallon system remove two cups of water from the fish zone daily and then add two cups of fresh water (dechlorinated if using tap water). Do the same for the 10 gallon control aquarium but only remove and replace one cup of water per day. This gives you a 40 day Hydraulic Detention Time (HDT) for both tanks.

You will need to make daily observations on your system and you should keep a journal with all the system design and construction details and daily observations. Some sort of magnification such as a magnifying glass or dissecting microscope is helpful. A test kit for water analysis is also very useful. This can allow you to control water quality by tracking pH, temperature, ammonia, orthophosphate, salinity, and other water quality indicators. In simpler systems you will not be able to measure dissolved oxygen levels without more expensive equipment so you will provide excess aeration so that this does not become a problem variable.

Get to know the organisms that are living in your system.

TimberFish will be offering a Table Top Model kit or package for the 10 and 20 gallon units. Except for the aquariums and ecoreactor baskets these kits could be used to operate larger systems with more elaborate versions able to run the Ecologically Integrated Agriculture systems. A complete kit for a 20 gallon Table Top Unit will comprise the following:

- a 20 gallon standard aquarium.

- a HDPE plastic framework to support and stabilize the various ecoreactors used in the system.

- HDPE plastic ecoreactor baskets and stick holders.

- required aeration and water transfer pumps with the required tubing and flow control valves and spreaders.

- a test kit for water quality measurements.

- a siphon for collecting solids from the tank floor.

- an operation manual.

- five different solutions for process control. These will include;

- a 10-10-10 liquid fertilizer with all the required nutrients and micronutrients for biological growth at the microorganism to larger animal levels.

- an acidic buffer for pH adjustment

- an alkaline buffer for pH adjustment

- an ammonia solution for Nitrogen/Phosphorus adjustment.

- an orthophosphate solution for Nitrogen/Phosphorus adjustment.

- a collection of glassware, sampling and eyedropper equipment.

The operation manual will include standard operating procedures for the various objectives and configurations. For example, consider a 20 gallon system that can meet Objective #4, running at pH7 with a Nitrogen/Phosphorus ratio of 4 to 1. After set up but before regular operation measure pH, ammonia, and orthophosphate. Add the 10-10-10 liquid fertilizer until either the ammonia concentration is at 0.5 ppm (mg/l) or the orthophosphate concentration is at 0.3 ppm. Whichever comes first. Then take daily measurements after the water exchange of temperature, pH, ammonia, and orthophosphate. Adjust with buffers and nutrient solutions as necessary to meet your operating parameters.

When starting up sometimes the water will become brown to dark brown. This will be as a result of tannins and humic acids leaching out of the wood chips and will be function of what wood chips you are using and how old they are. When this occurs you can take the wood chip ecoreactors and put them in a bioreactor tank where they will be completely submerged and aerate them for several weeks along with your inoculum. Then return the wood chip ecoreactors to your 20 gallon system and allow the bioreactor to settle. Siphon some of the settled solids out of the bioreactor and add them to the 20 gallon experimental tank. Then resume aeration of the bioreactor and the color should gradually disappear.

The following descriptions of Ecotechnology present examples of how you can do this. How you can learn to understand the participatory ecological perspective by actually doing ecotechnology.

Most of these examples describe projects that you can do yourself, in your home, or office, or classroom; or backyard, garden, woods, or farm you have access to.

Microbial Tank Farm (1973)

This is where it all started for me in 1973. A backyard project that served as the initial project to demonstrate that unused plant material such as weeds could be degraded by microbes which could then could be used to feed fish. I used 55 gallon drums, five gallon pails, one gallon jugs, and a variety of other bottles, tubing, and pipes to use goldenrod and other weeds in a microbial process to feed fish.

|

Here are more photos of the Microbial Tank Farm. MTF Photos

Table Top Models (2024)

51 years later the Microbial Tank Farm evolved into the Table Top Models. Here is a sample setup for a 10 and 20 gallon system.

|

From left to right: phase contrast microscope, dissecting microscope, gram scale, water quality test kit, 10 gallon unit (operating), 20 gallon unit (assembled but not operational).

Basement/garage systems

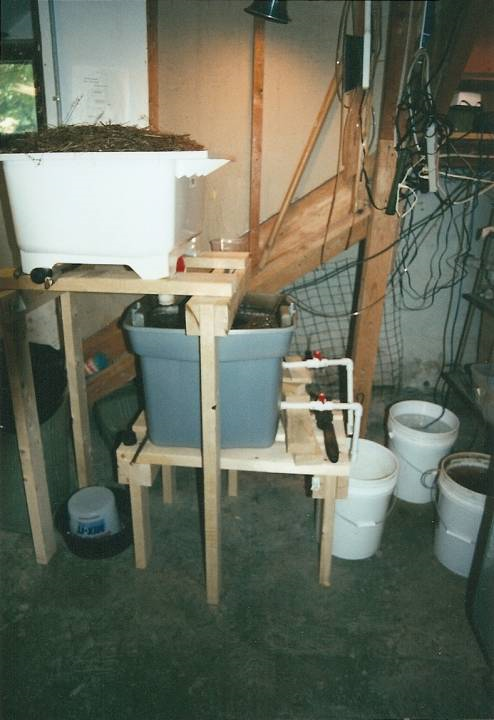

Tabletop systems will be in the 10 to 20 gallon range but they can be expanded to 50 to 100 gallons that can be installed in basements, garages, or barns. This example shows a typical system that was initially installed in a basement but subsequently moved to a garage. It comprises a wash tub containing wood chips and plant materials, a large storage bin which serves as an aerated bioreactor, several 5 gallon pails for liquid transfers, a 10 gallon aquarium, small storage bin, a number of small containers, and an aquarium type aerator. In this implementation water transfers were done manually. At this scale some water testing equipment for pH, ammonia, ortho phosphorus, temperature, and a dissecting microscope are helpful.

|  |

Here are more photos of the Basement Garage System. BG Photos

Woodland pond system

This shows how the basement/garage sized systems can be scaled up to 1,000 gallons plus. At this scale larger fish can be grown that eat only the food produced within the system. This application is located in a natural environment and demonstrates how this ecotechnology is fully compatible with the existing environments of our native forests and wetlands.

|  |

Here are more photos of the Woodland System. WP Photos

Woodland tank systems

Just downstream from the woodland pond we installed a tanked version of the TimberFish Technology. This was fed by a gravity stream from the overflow standpipe in the woodland pond. This flow could be reduced if desired with a bypass valve or more precisely controlled with a variable speed feed pump from the woodland pond effluent stream. The tanked version allow us to feed commercial pellets, meet high quality discharge standards, and supplement the fish feed with natural food that was grown within the system. This comprised snails, worms, insect larvae, and a microbial biofloc. The system comprised two 1,000 gallon tanks with an auxiliary 55 gallon drum and/or a 60 gallon supplemental tank. Aeration and recycle pumps we also used. Various configurations of this system were operated from 2008 to 2015.

|  |

Here are more photos of the Woodland Tank Systems. WTPhotos

Freshwater Institute Field Trial

After the success of the Woodland Tank System’s initial run in Westfield, New York, we contracted with the Freshwater Institute, a division of the Conservation Fund, to do an independent field trial of the TimberFish Technology. This was performed in 2010 and 2011 at their facility in Shepherdstown, West Virginia.

|  |

Here are more photos of the Freshwater Institute Field Trial. FWIphotos

Here is a copy of the Freshwater Institute's Final Report. FWIReport

Mobile Trailer Unit

In 1999 we built a mobile unit that could be mounted on a trailer and transported to sites and used as a demonstration.

|  |

Here are more photos of the Mobile Trailer Unit. MTUphotos

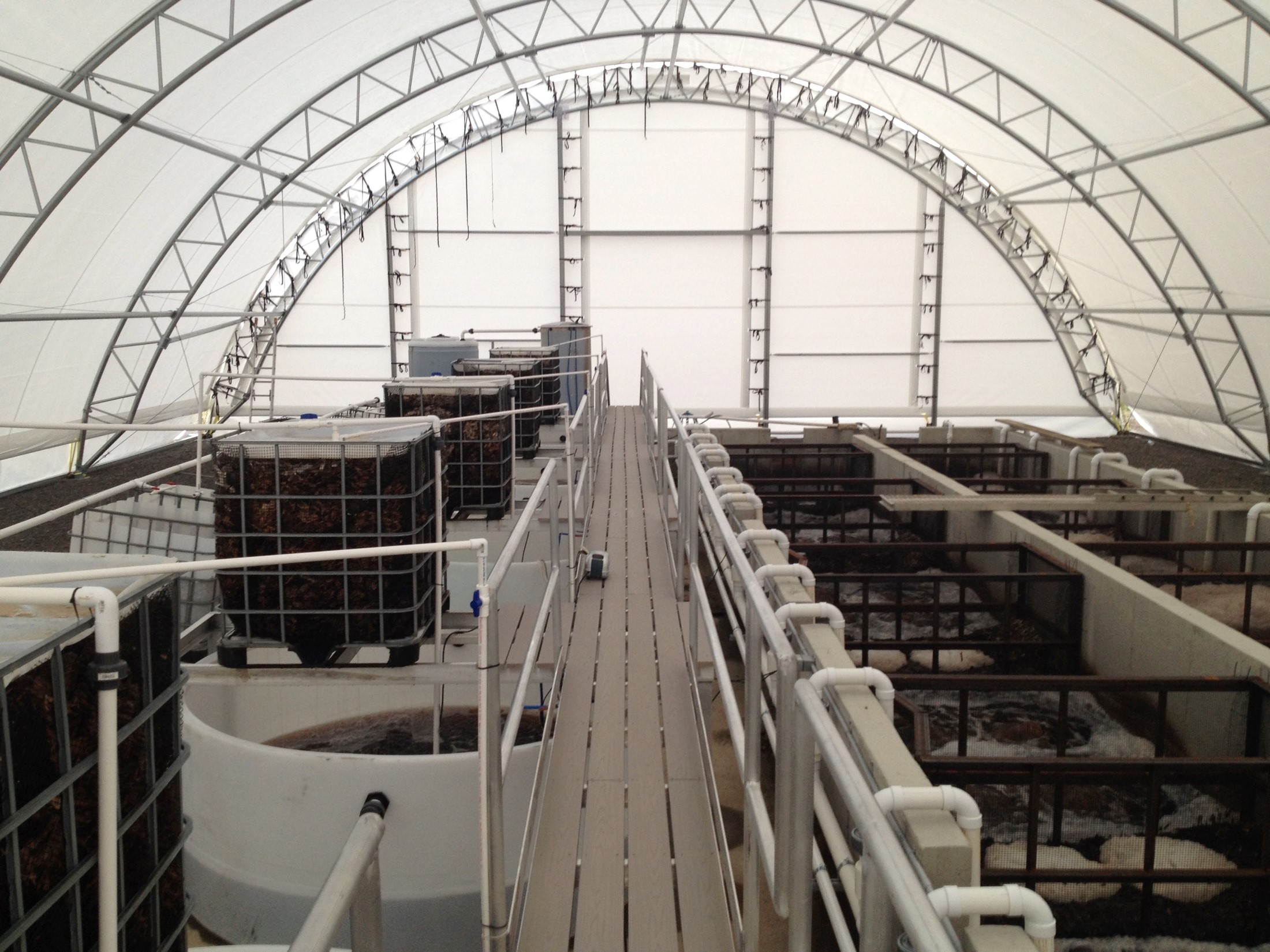

Five & 20 system in Westfield

Our largest system was started in 2016 at the Five & 20 Spirits & Brewing facility in Westfield, New York.

|  |

Here are more photos of the TimberFish system at Five & 20. FTphotos

For more information on the TimberFish system at Five & 20 in Westfield see our website, https://timberfishtech.com/ and the video by Anthony Arthur Augustine on TimberFish Technologies.