TimberFish Ecotechnology

The Process

The TimberFish Technology (TFT) combines elements from Recirculating Aquaculture Systems, Integrated Multi-Trophic Aquaculture, and Biological Municipal Wastewater Treatment. The resulting technology has been implemented in a complex and diversified ecosystem production facility that raises fish and other seafood utilizing plant material harvested from non- agricultural land and production residuals from the food and beverage industries as sole material inputs. Large scale implementation of this ecotechnology can actually mitigate and reverse Climate Change. See our Global Application Program.

The TFT mimics the natural food-chain of fish and macro-invertebrates. It combines water purification and underutilized biomass to produce salable seafood and biofuels. The process is local, sustainable, environmentally friendly, removes solid and soluble pollutants from water; creates contaminant-free seafood; is not dependent on chemical use; and generates enhanced biofuels. TFT is economically attractive, providing a commercial driver for the global proliferation of environmental best practices including reforestation and deforestation avoidance.

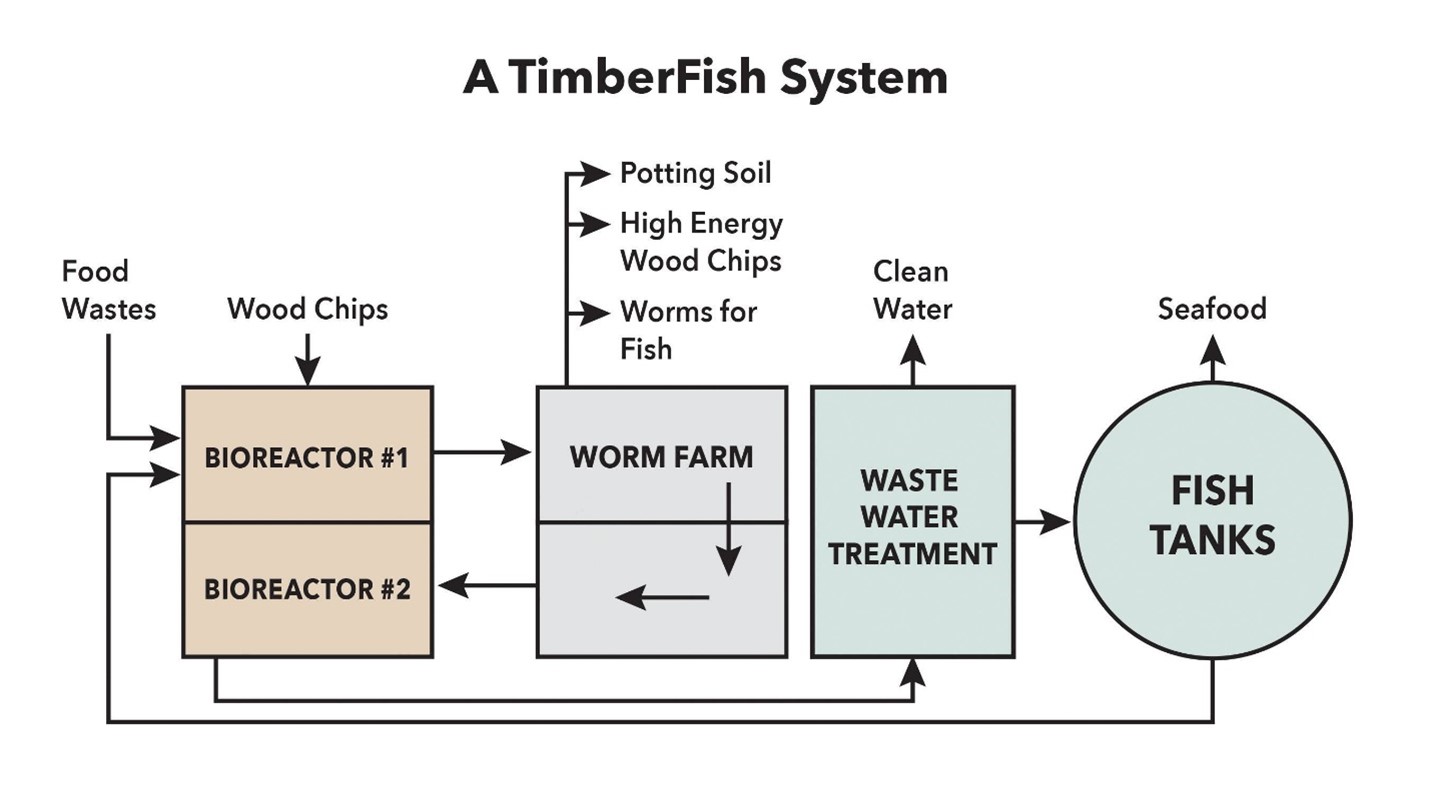

The process comprises a series of interconnected internal recycle flows and sub environments that contain a large variety of organisms ranging from microbes, to invertebrates, and fish. It works by combining plant material with nutrients contained in by-product waste streams. The microbes are grown in this mixture and then become food for the invertebrates that are also resident within the system. The structure of the system is such that it is easy to provide these invertebrates to the product fish or other seafood that also reside within the system for their consumption.

The TFT system is designed to contain an extremely large variety of microorganisms and many different species of invertebrates. All of these can reside in various physical sub environments ranging from suspended floc structures and single cell aggregates to fixed film layers that will reside on the matrices comprising wood chips, grain hulls, and other grain and fruit non fermented residues.

A general schematic of the process is as follows.

Here is a technical description of this ecotechnology.

To resolve the environmental problems contributed to and created by modern agriculture the TFT technology presents a method of producing food while sequestering large amounts of carbon compared to modern agriculture. The patented design combines a harvested plant material degradation system, a microbial growth system in fluid contact with the harvested plant material degradation system, and an intermediary animal system in biomass-transfer interaction with the microbial growth system.

TFT invented a method of agricultural production in which diverse mixed plant communities are grown, maintained, and partially harvested in a periodic manner so that significant quantities of carbon are sequestered within the persisting plant communities. The periodically harvested plant material is collected and concentrated in a physically defined space. There it is microbially broken down, converted into a microbial biomass which is processed into food for human consumption or animal feeds, or is fed to one or more varieties of small intermediary animals which are in turn used directly for food, used as an animal feed, or used as a raw material for the production of processed foods and animal feeds. The animal excreta or unused byproducts of each stage of production may be recycled back to prior stages where they are used as inputs of nutrients and biodegradable raw materials. Water may also be recycled within the system and parts of the microbial growth systems and production lands can serve a water purification and filtration function.

The Timber Fish system can use any material (Plant Material) produced by a photosynthetic reaction in plants. Generally the Harvested Plant Material will include Plant Material grown in forests or woodlots and will include whole trees and bushes, logs, branches, leaves, and roots. Plant Material may also include grasses, reeds, aquatic plants, shrubs, bushes, yard wastes, and a variety of agricultural products and byproducts such as corn stover, straw, hay, vegetable and fruit processing waste, etc. Plant material may also include various produced or manufactured materials and products such as lumber, paper, cardboard, fabric, and the like. The harvesting of plant material from natural ecosystems can be done in an intermittent and controlled manner that maintains and enhances the aesthetic nature and biodynamic stability of our natural environments. This will promote the maintenance and protection of the many current forest and wetland habitats that are currently threatened by modern agriculture and industrial and suburban growth. In addition proper forest management can maximize the production of more valuable, high quality species, which can also be harvested in a controlled manner.

The Plant Material is collected in a container, pond, tank, or the like, or is piled or placed on a pad or in a contained area where liquid emanating from the material can be collected. The Plant Material is then subjected to a microbial treatment process in which various constituents of the Plant Material are converted into a microbial cell mass or oxidized for energy. The constituents most generally converted in this manner usually include cytoplasmic sap comprising proteins, nucleic acids, fats, oils, sugars and other molecular components of the plant cells, and the more easily digested fraction of the structural components of the Plant Material such as cellulose or parts of the hemicellulose fraction of the Plant Material. Usually the fraction of the Plant Material which is converted into a microbial biomass is about 40 to 60 % of the total mass. However, in some applications, as little as 5 to 10% or as much as 95% of the Plant Material may be converted.

During the bioconversion process, the Plant Material is usually submerged in water, either continuously or periodically. In other configurations it may be stacked or placed either above water or on a pad or other impervious surface and occasionally sprayed or irrigated with water. Nutrients or fertilizers comprising sources of nitrogen, phosphorus, potassium, and other elements necessary for microbial growth may be introduced into the water or otherwise applied to the Plant Material to facilitate the growth of the microorganisms.

As a part of the bioconversion process microbes and part of the microbial biomass may be continually or intermittently removed from the Plant Material. This may involve physical separation techniques such as washing, rinsing, irrigating, hosing or other methods involving water or other aqueous solutions. It also could involve other physical methods which could remove small particles of degraded material which have microbes attached to their surfaces or embedded within the small particles. These physical methods of separation could involve blowing air on the material or shaking or otherwise mechanically disturbing the material to loosen and remove microbe containing small particles.

Other methods of continually or intermittently removing microbes from the Plant Material may involve the use of other biological organisms such as small fish, insects, snails, worms, or other macro-invertebrates. These organisms may have continuous or intermittent access to the Plant Material during which time they may collect or consume the microbes. The organisms may be separated from the collected Plant Material or they may be periodically harvested from within the collected Plant Material, either by various mechanical means, or through the use of other larger organisms such as larger fish, reptiles, amphibians, birds or mammals.

Once the microbial conversion and treatment process has progressed to a desired level of production of microbes, or destruction of the Plant Material, the remaining material (designated hereafter as the Biologically Processed Material) is collected and prepared for energy production. This preparation process may include rinsing, irrigating, hosing or other methods of cleaning the material to remove residual microbes and other collecting organisms.

The resulting Biologically Processed Material will comprise a different distribution of component compounds than will the Plant Material from which it was produced. Thus the Biologically Processed Material will contain relatively fewer nutrients, proteins, nucleic acids, sugars, starches, fats, oils, and other readily degradable substances than the original Plant Material. The Biologically Processed Material will also contain relatively less cellulose and hemicellulose, and relatively more lignin, than will the source Plant Material.

Biologically Processed Material produced from the Timber Fish system could produce fewer greenhouse gases if burned or incinerated than original or "raw" Plant Material. This may occur because nutrients such as nitrogen and sulfur would have been consumed by the biological treatment process and removed with the microbial biomass.

Once the Biologically Processed Material has been produced it is then further processed into an appropriate substrate for energy production. The further processing will usually entail drying and often will involve a mechanical process to convert the Biologically Processed Material into small particles. The mechanical process may involve grinding, shredding, chipping, chopping or other similar processes. The drying process may occur before, during, or after the mechanical process, or it may occur during some combination of these.

Once the Biologically Processed Material has been appropriately prepared physically and mechanically it becomes an Energy Substrate that can be used as a feedstock for an energy production process or a process which produces fuels or other energy products. The Energy Substrate may be used for straight incineration or combustion to provide heat to run a generator or fire a boiler. The Energy Substrate may also be used as a feedstock for a pyrolytic, gasification, or liquefaction process in which a variety of other usable energy products as well as heat may be produced. The useable energy products could include carbon, charcoal, alcohols, liquid oils, biodiesel, and burnable gases such as methane or a variety of mixtures of methane, hydrogen and carbon monoxide.

When this method is combined with a program of global reforestation and the steady state maintenance of existing and new diversified forests, it may result in a significant reduction in the concentrations of carbon dioxide and other greenhouse gases in the atmosphere. Other system design benefits include the economic incentivization of a global reforestation effort and the development of a microbial biomass which represents a new uncontaminated material which can be converted into a new food source capable of providing a high protein diet for all of the existing and projected populations of the world. A significant reduction in the nutrient pollution of surface and ground waters will also be realized, in addition to the preservation of biological biodiversity, biodynamic stability, and natural ecological habitats.

Here is a list of US patents that have been issued to Jere Northrop and assigned to TimberFish LLC that cover this ecotechnology.

United States Patent No. 9,764,977, “Process for the Treatment of Biological Materials and Wastewater”, issued on September 19, 2017. This patent was derived from application US 13/821,744, the remainder of which was filed as a continuation application US/15/682,140, see below.

United States Patent No. 9,681,644, "Process and Method for Optimizing Production of Food and Feed", issued on June 20, 2017. This patent was derived from application US 13/580,299, the remainder of which was filed as a continuation application US/15/599,954,see below.

United States Patent No. 10,448,620, entitled “Nutrient Capture System” issued on October 22, 2019. This patent was derived from United States Application No. 14/505,789 which was filed with the US Patent and Trademark Office (USPTO) on October 3, 2014. The application corresponds to a provisional application filed with the USPTO on October 3, 2013.

United States Patent No. 10,448,620, entitled “Process for the Treatment of Biological Materials and Wastewater” issued on November 5, 2019. This patent was derived from application US/15/682,140 which was filed with the US Patent and Trademark Office (USPTO) on August 21, 2017 as a continuation of US 13/821,744, which was filed with the US Patent and Trademark Office (USPTO) on March 8, 2013, and was an election of an international PCT patent application filed on September 12, 2011. The application corresponds to a provisional application filed with the USPTO on September 10, 2010. Part of US 13/821,744 was issued as patent No. 9,681,644, on September 19, 2017, see above.

United States Patent No. 10,524,490, entitled “Process and Method for Optimizing Production of Food and Feed” issued on January 7, 2020. This patent was derived from application US/15/599,954, which was filed with the US Patent and Trademark Office (USPTO) on May 19, 2017, as a continuation of US 13/580,299 which was filed on August 21, 2012. This was an election of an international PCT patent application filed on February 25, 2011, and corresponded to a provisional application filed with the USPTO on February 25, 2010. Part of US 13/580,299 was issued as patent No. 9,681,644, "Process and Method for Optimizing Production of Food and Feed", on June 20, 2017, see above.

Pending Published Application:

US 11/705,895 A patent application entitled “System for Producing Food and Feed”, US 11/705,895, was filed with the US Patent and Trademark Office (USPTO) on February 13, 2007.

Pending Non Published Application:

On July 31, 2024 a provisional application #63/677,717 for Ecologically Integrated Agriculture was filed with the US Patent and Trademark Office (USPTO).

On April 3, 2025 a provisional application #63/782,991 for Ecological Aquaculture Forestry Platform was filed with the US Patent and Trademark Office (USPTO).

A forerunner of the TimberFish Technology was the first two generations of the Bion Technology that was developed from 1988 to 2008. This technology was derived from the same emerging philosophical and theoretical foundation as the TimberFish Technology but in a more primitive form. It is summarized here as a historical and technical reference.