Sustainability Program

Environmental Sustainability Program for Universities

Our program for universities can serve as a stand alone program, or can be seamlessly and economically integrated into an existing sustainability program. It comprises a series of ecotechnology projects that range from tabletop models to full scale production systems. These demonstrate how currently unused plant material, such as wood chips from forests, can be converted into seafood, renewable energy, clean water, and slow release potting soils and soil amendments. The program highlights the ecotechnologies developed by TimberFish Technologies.

Thus TimberFish will issue a site license to a university for their use in any and all university educational and research activities and applications. These can include university promotional and fund raising events and initiatives, research grant applications and programs, and student entrepreneurial and technology transfer activities. This would also apply to other educational institutions such as high schools or colleges.

This proposal describes an ecological, economic, and educational sustainability program modeled on a principle of participatory ecotechnology. It is multidisciplinary, hands on, and integrally related to the real world. The program offers many benefits to students and others by demonstrating the meaning of sustainability in local and entrepreneurial applications. It also will integrate the knowledge they obtain in the academic areas of the natural sciences (biology chemistry, physics), applied technology (engineering, computer science, fabrication, construction), business (economics, entrepreneurial start ups, marketing), mathematics, sociology, philosophy, and art.

The program offers significant advantages to a university. By offering an environmental sustainability program that is unique, practical, and scalable to global application it will be attractive to students who are very concerned about the looming issue of Climate Change, and who don’t know what they can do about it. The public relations that can be obtained from this will also be attractive to donors and supporters of an educational institution, and for potential corporate sponsors who are looking for ways to improve their environmental image.

The university program is centered on student participation in the building and operation of ecotechnology systems that can produce seafood from local sustainably harvested forests and woodlots. This can incentivize reforestation and deforestation avoidance, which will help mitigate Climate Change.

The proposed program comprises table top units of 10 to 100 gallons which can be expanded to lab units of up to 1,000 gallons or more. Because the process is modular and scalable small units utilize the same biology as large units. Thus the program could lead to larger scale units such as our mobile demonstration unit. All of this is to achieve the global installation of production units capable of producing significant quantities of fish and other seafood. See our Ecologically Integrated Agriculture program (link)

The start of the program will center on Table Top Models that can be constructed and operated by university students and personnel. To assist in the dissemination of this technology we hope to be marketing working table top units and programs that show how this technology works and why it is important. These will be offered to educational institutions that don’t want to build units themselves but still want to implement sustainability programs and STEMPA (Science, Technology. Engineering, Math, Philosophy, and Art) curricula. They will also be offered to groups or individuals that are concerned about Climate Change and may be skeptical about current efforts to resolve the issue.

The Table Top Model Program will include a variety of sizes but will feature a 20 gallon unit with accessories for high schools and colleges. Accessories could include: Water quality monitoring test kit; Magnification devices such as general purpose microscopes and Dissecting and Phase Contrast Microscopes; Gram scale; Siphon; Associated glassware and equipment. Instructions as to how to build these units are available and we are working to provide pre assembled units with test kits as soon as possible.

As another part of the proposed program TimberFish could offer a mobile demonstration system (the Demo) to a university. The Demo is a trailer mounted unit with its own set of electronic controls and can be maintained and operated by students, faculty or staff. It also could be remotely operated and/or monitored by TimberFish personnel. It can be located anywhere that electrical power is available, or it can run with its own generator. Connections to water and sewers are preferred but are not absolutely necessary as the system can operate as a zero discharge or land application system for a short demonstration period. Appropriate permits for the demo will be obtained from NYS DEC for any form of the demonstration.

TimberFish has operated a commercial pilot system at the Five & 20 Spirits & Brewing facility in Westfield, New York that illustrates what a scale up of this system might look like. This facility received all of the byproducts and production waste streams (no sanitary wastes) from the distillery and its companion brewery. The system grew fish and freshwater shrimp, recycled and treated all solid and dissolved wastes, produced a high energy wood chip residual which could be a renewable biofuel, and discharged a high quality effluent under strict permits issued by the New York State Department of Environmental Conservation.

This program has an additional benefit in that it provides a template for the revival and continuation of the “Global Village” concept that Marshall McLuhan introduced in the 1960s. This could now include a series of local sustainable green circular economies which would integrate sociological, economic, and environmental factors into a sustainable future for humanity. It presents a potential path to resolve the issues of global Climate Change and environmental pollution.

Description of the Ecotechnology Process:

TimberFish creates a new food chain that is not dependent on existing agricultural or marine resources. Clean waste streams from restaurants, recirculating aquaculture systems, and the food and beverage industries can be combined with a wide variety of non agricultural plant materials such as wood chips that can be sustainably harvested from diversified ecosystems such as forests. This combination is used to grow microbes, which are fed to invertebrates, which are fed to fish and shrimp. The resulting seafood is contaminant free and locally produced. The only other outputs are clean water, a high energy clean residual wood chip, and potting soil. The process is non-polluting, ecologically sustainable, and economically competitive in todays' market.

The TimberFish Technology (TFT) combines elements from Recirculating Aquaculture Systems, Integrated Multi-Trophic Aquaculture, and Biological Municipal Wastewater Treatment. The resulting technology was implemented in a complex and diversified ecosystem production facility that raised fish and other seafood utilizing plant material harvested from non- agricultural land and production residuals from the food and beverage industries as sole material inputs.

The TFT mimics the natural food-chain of fish and macro-invertebrates. It combines water purification and underutilized biomass to produce salable seafood, clean water, soil amendments, and biofuels. The process is local, sustainable, environmentally friendly, removes solid and soluble pollutants from water; creates contaminant-free seafood; is not dependent on chemical use; and generates a high energy residual wood chip that can be used for heating, generation of electricity, or the production of biofuels. TFT is economically attractive, providing a commercial driver for the global proliferation of environmental best practices including reforestation and deforestation avoidance.

The process comprises a series of interconnected internal recycle flows and sub environments that contain a large variety of organisms ranging from microbes, to invertebrates, and fish. It works by combining plant material with nutrients contained in by-product waste streams. The microbes are grown in this mixture and then become food for the invertebrates that are also resident within the system. The structure of the system is such that it is easy to provide these invertebrates to the product fish or other seafood that also reside within the system for their consumption.

The TFT system is designed to contain an extremely large variety of microorganisms and many different species of invertebrates. All of these can reside in various physical sub environments ranging from suspended floc structures and single cell aggregates to fixed film layers that will reside on the matrices comprising wood chips, grain hulls, and other grain and fruit non fermented residues.

Table Top Model Description:

Purpose:

The TimberFish Technology is a new form of Ecologically Integrated Agriculture that can mitigate Climate Change by using green and dead wood from sustainably managed forests to locally produce contaminant free seafood, renewable energy, and clean water. The technology is scalable and works equally well at the table top level, or at a level that can produce a million pounds of seafood per year. The Table Top Model provides a way for everyone to understand this technology by actually operating a working system in their home, or classroom, or virtually any other locally available space in their neighborhood or community. The interaction with the Model will generate an understanding of ecological thinking and how that can lead to resolving Climate Change and other environmental problems.

These are aquaculture systems and can be used for fresh water or salt water organisms, which can vary to include warm or cold water species depending on your local environment or interests. Fish will be the most commonly grown organisms but a variety of mollusks (snails, clams, etc.) and crustaceans (shrimp, crayfish, etc.) can also be grown.

It is important to remember that when working with ecosystems in these Table Top Models the ecological processes always function. They may not give you the “experimental” result or demonstration that you expected, but that just means that you were not doing the experiment or demonstration that you thought you were doing. Putting wood chips and nutrients and water together will result in microbial growth. They are everywhere. Putting a little dirt from around a tree in the mix will speed things up. Adding small samples from local ponds, streams, ditches, puddles, muds, etc., will speed it up even more.

Table Top Models include 20 gallon aquariums and four ecoreactors.

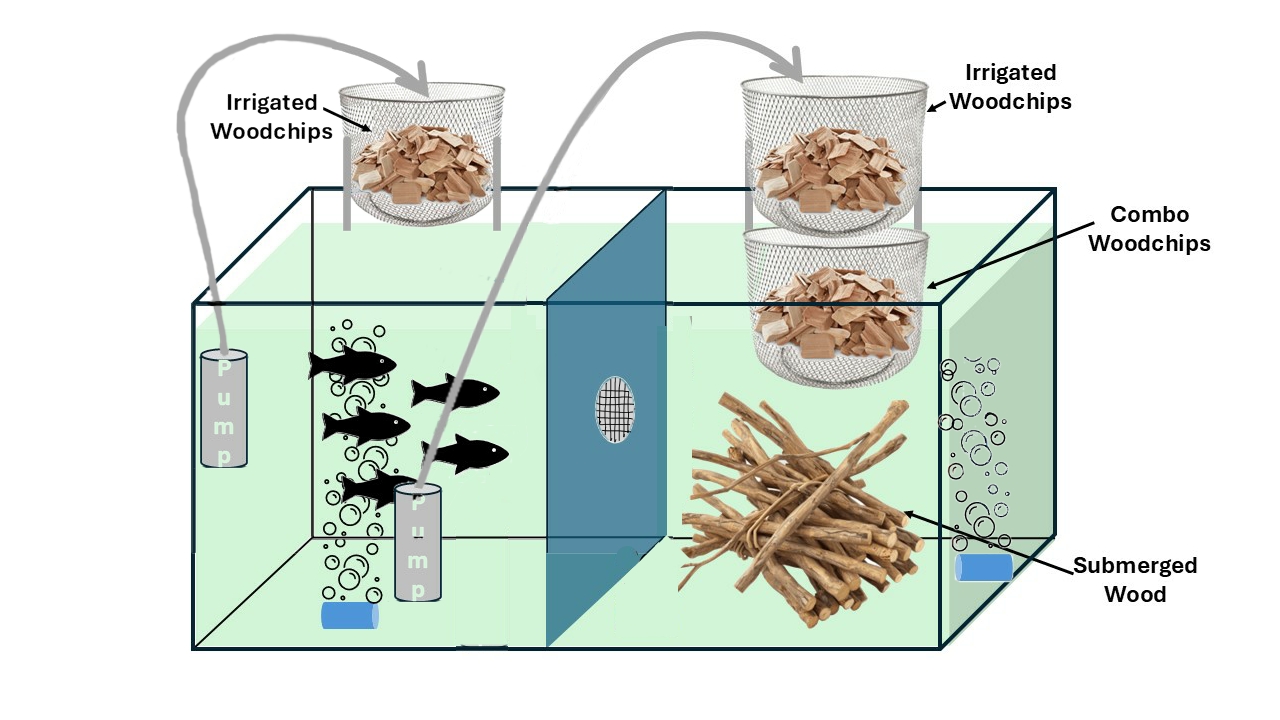

Here is a conceptualized diagram of such a unit.

Here is a photo of a 20 gallon tank with four ecoreactors.

These ecosystems with an aquarium and four ecoreactors can be set up in a variety of configurations and can be operated to achieve the following objectives.

Objectives:

- Show that fish and macroinvertebrates such as shrimp, snails, clams, etc., can live and grow in an environment that contains only wood chips and nutrients without any other food source.

- Identify various microorganisms and smaller invertebrates that adapt to, and thrive within, the system, and which serve as a food source for the fish and macroinvertebrates.

- Quantitate the production process by measuring input variables and obtained outputs, and calculating how many pounds of fish or macroinvertebrates can be produced from a given weight of wood and given weights of nitrogen and phosphorus supplied as nutrients.

- Optimize the production process by studying a wide range of process variables. These can include;

- Various species of fish and macroinvertebrates.

- the quantities of wood and nutrients provided,

- the configuration of the various zones, recycle flows, and pumping and aeration rates,

- water quality parameters such as pH, temperature, salinity, dissolved oxygen levels, nitrogen and phosphorus concentrations, alkalinity, micronutrients, etc.

Accessories that would be required to meet each of the objectives:

- Water testing kit to measure pH, ammonia, and orthophosphate. Chemical solutions to provide acid and alkaline buffers, and input ammonia, orthophosphate, and other required micronutrients.

- Sampling equipment. Some sort of magnification device which can range from a simply magnifying glass to various levels of microscopes. These could include; a general purpose microscope to dissecting microscopes for small invertebrates, and phase contrast microscopes for bacteria.

- Measuring equipment to accurately quantify volumes of liquid solutions applied to various scales to weigh wood chips used and product animals harvested. Drying oven. Water testing kit needs to include salinity, total dissolved solids, suspended solids, alkalinity.

- Water testing kit needs to include Dissolved Oxygen and ORP (Oxygen Reduction Potential). Accurate flow measuring for recycle and aeration. Some lab analysis for COD (Chemical Oxygen Demand), TKN (Total Kjeldahl Nitrogen), and Total Phosphorus. Muffle furnace for Total Solids determination

Procedure:

For the project it is helpful if you start by setting up a 10 gallon conventional aquarium to raise the organisms used in the project (Guppies or goldfish are good started species for this). This will serve as a control and facilitate comparison with standard fish raising systems. The TimberFish system is an ecosystem and as such will contain many different types and numbers of living organisms. You will need to know, or learn, who they are, what they require, what they like, how they reproduce, how they interact with each other, and how they interact with you. Since the apex or product animal in this ecosystem can range from fish to various macroinvertebrates (shrimp, crayfish, snails, clams, etc.) you should know and be familiar with how to raise them conventionally.

The project tank can be any 20 or more gallon fish tank. You will need a divider that can separate the aquarium into fish zones and wood zones. This can be a sheet of plastic, screen, glass, or other similar material, that you can construct with a hole to act as a passageway for the fish to swim from one zone to the next and back. In the diagramed example a plastic sheet is cut to fit the sides of the tank and in which a one to two inch hole is cut to allow fish and water passage between zones.

The system will comprise several types of baskets to hold wood chips. Two of these, the perched chip baskets, will hold wood chips that are irrigated with water but never submerged..

A third basket, the combo basket, will hold chips, some of which will be submerged while others will be above the water line and hence just irrigated.

These baskets can be constructed from hardware cloth or other screens that have holes or opening from about one quarter to one half inch (one centimeter) to allow water, biomass, and small animals to pass but will retain the wood chips. These can also be made by drilling holes in plastic containers, by using food colanders, or other plastic objects.

In the photographed example these ecoreactors are made of a plastic hardware cloth. The irrigated baskets are supported above the tank while the combo basket will be placed so that some of the chips will be above the waterline and others will be below the waterline. The Irrigated baskets will be separated from the Combo basket, by an air zone, but will have "feet" or some sidewall extension so that there is a wet direct connection between the two baskets. This will allow snails to travel from the bottom of the tank to the top of the Irrigated basket and back if they so desire, and they will.

At the bottom of the wood zone there will be a stick structured ecoreactor. This is a coated fence type wire mesh with 2 by 3 inch holes that support sticks in a vertical position. This will allow fish to freely swim around the sticks and eat any microbial floc or invertebrate organisms attached to the sticks.

Examples of organisms that populate each ecoreactor will include small earthworms for the Irrigated baskets, Oligochaetes (a small diameter aquatic worm) in the combo basket, and Gammarus (an aquatic fairy shrimp or scud) for the tank zone. Freshwater snails will inhabit all four ecoreactor zones. There will be a myriad of other invertebrates that will appear but these will be among the bigger ones that can be easily seen by the observer.

The system will also need an air pump with two outlet nozzles for air tubing (or one nozzle with a stream splitter). This will allow two air lines going to two aeration stones. One of these will be in the fish zone and the other will be in the wood zone.

The system will also need two or three recycle pumps to transfer water from various locations in the tank to the top of the perched irrigated wood chip baskets. These recycle pumps need flow controllers or controllable valves located in the recycle lines. Additionally you will also need a five gallon pail and a siphon apparatus for collecting solids from the bottom of the fish zone when needed. These solids will be returned to the top of one of the irrigated baskets, whichever one is located above the combo basket in the wood zone.

Start Up:

Set up the conventional aquarium and start growing the organisms you will use in the experiment. Your water source is important for your project. If you will use a municipal water source you will need to make sure it is dechlorinated. You can do this by letting it stand in an open pail for a day before adding it to your system.

Once the control aquarium is set up and running add about 10 gallons of water (dechlorinated if you are going to use a municipal water source) to the 20 gallon experimental tank. Then take a five gallon pail and go to a small local pond or stream. Collect five gallons of water and put that in your experimental tank.

Then return to the pond or stream and collect a variety of samples of muck, sediment, aquatic vegetation, and dead plant material that is in and associated with the water source. Look for and collect any small organisms you can find that are living in the pond or stream. In particular these should include any larger invertebrates such as aquatic worms and snails. A magnifying glass can be helpful here. Put all your samples in another five gallons of water. Bring the sample pail back and aerate it for a day or two. Allow it to stabilize to your room temperature and then stop aeration and let the solids settle to the bottom of the pail. Decant it into your experimental tank in the wood zone side. Examine the settled solids and if you can see any organism activity try to collect that and add it and some of the solids to the experimental tank wood zone as well. Activate all aeration and recirculation flows but do not add fish yet.

Operation:

Once your system has run for a week or more you can add fish or other product animals from your conventional fish tank. You need to add fresh water daily to prevent salinity buildup. So for a 20 gallon system remove two cups of water from the fish zone daily and then add two cups of fresh water (dechlorinated if using tap water). Do the same for the 10 gallon control aquarium but only remove and replace one cup of water per day. This gives you a 40 day Hydraulic Detention Time (HDT) for both tanks.

You will need to make daily observations on your system and you should keep a journal with all the system design and construction details and daily observations. Some sort of magnification such as a magnifying glass or dissecting microscope is helpful. A test kit for water analysis is also very useful. This can allow you to control water quality by tracking pH, temperature, ammonia, orthophosphate, salinity, and other water quality indicators. In simpler systems you will not be able to measure dissolved oxygen levels without more expensive equipment so you will provide excess aeration so that this does not become a problem variable.

Get to know the organisms that are living in your system.

For more detailed descriptions of the Table Top Units see https://www.e-c-o.net/wiki/Econet/TimberFishTableTopUnit

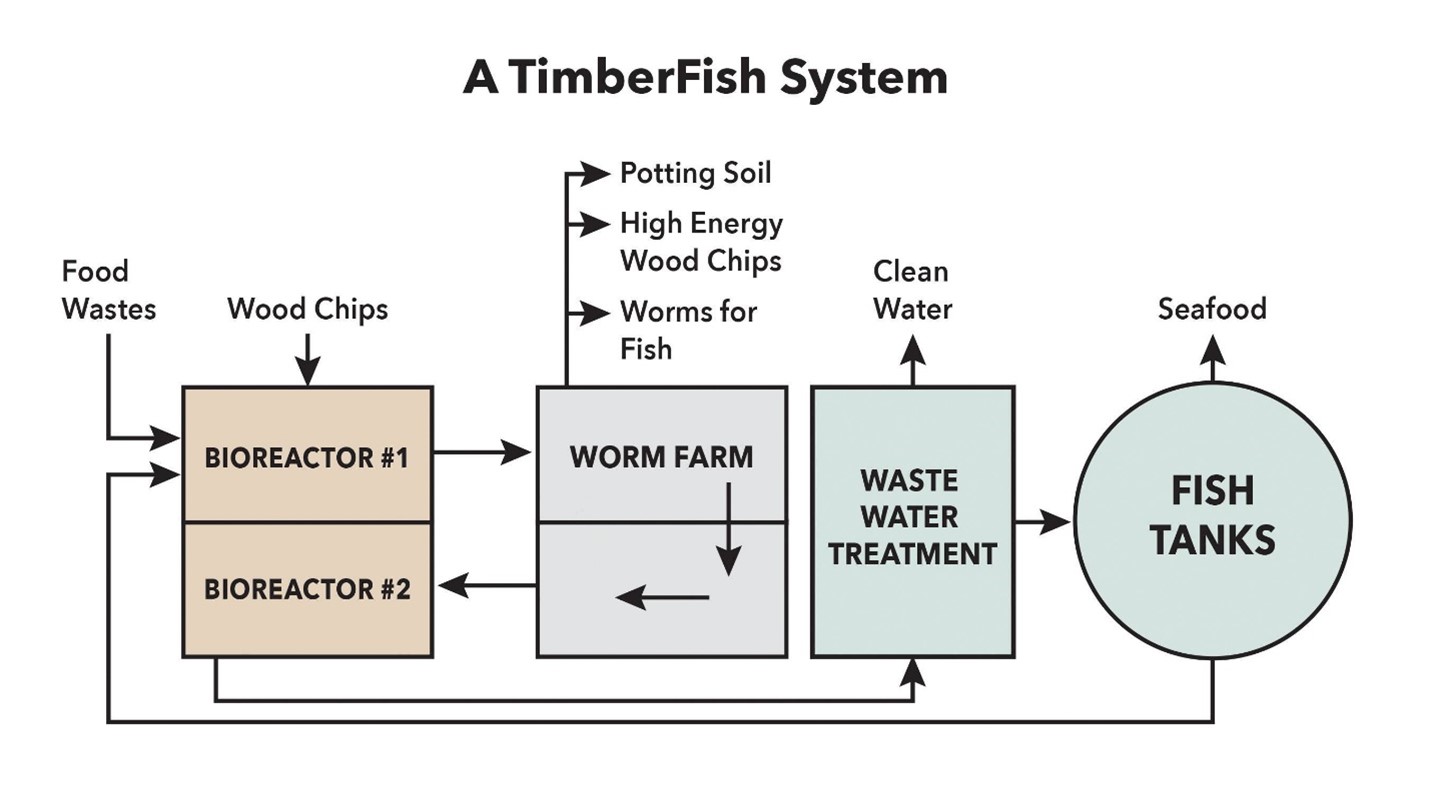

Larger systems will usually involve a different configuration but the same biology. A general schematic of such an application is as follows.

In this application Food Waste can comprise any non toxic waste, wastewater, or byproducts from food production and processing facilities, as well as such wastes from restaurants or cafeterias.

The Mobile Demonstration System

TimberFish has a small demonstration system (the Demo) that can illustrate this technology and which can be temporarily or permanently installed and operated for educational and research purposes at the university. The Demo is trailer mounted with its own set of electronic controls and can be operated remotely by TimberFish personnel. It also can be detached from the trailer and can be located anywhere that electrical power is available, or it can run with its own generator. Connections to water and sewers are preferred but are not absolutely necessary as the system can operate as a zero discharge system for a brief demonstration period.

This system requires no inputs other than a clean non toxic nutrient stream and wood chips sustainable harvested from nearby forests and woodlots. It discharges a tertiary treatment quality effluent that can be land applied or discharged to a sewer or receiving water under strict permit regulations. Partially degraded wood chips constitute a high energy residual that can be used to generate heat, electricity, or biofuels. The only other output product of the process is a potting soil type material.

The non toxic nutrient inputs to the system could be from a low protein commercial fish feed pellet that would be fed to the fish in the fish tank, or it could be from a food or food processing waste. In either case the aquaculture waste from the fish tank would be recycled back to the bioreactors.

Because this is a modular technology it can be implemented gradually and carefully studied and researched prior to any larger scale research or technology transfer applications. Since this is a portable system that is trailer mounted it can be easily removed if desired. It contains all required process control and monitoring equipment and can be remotely monitored.

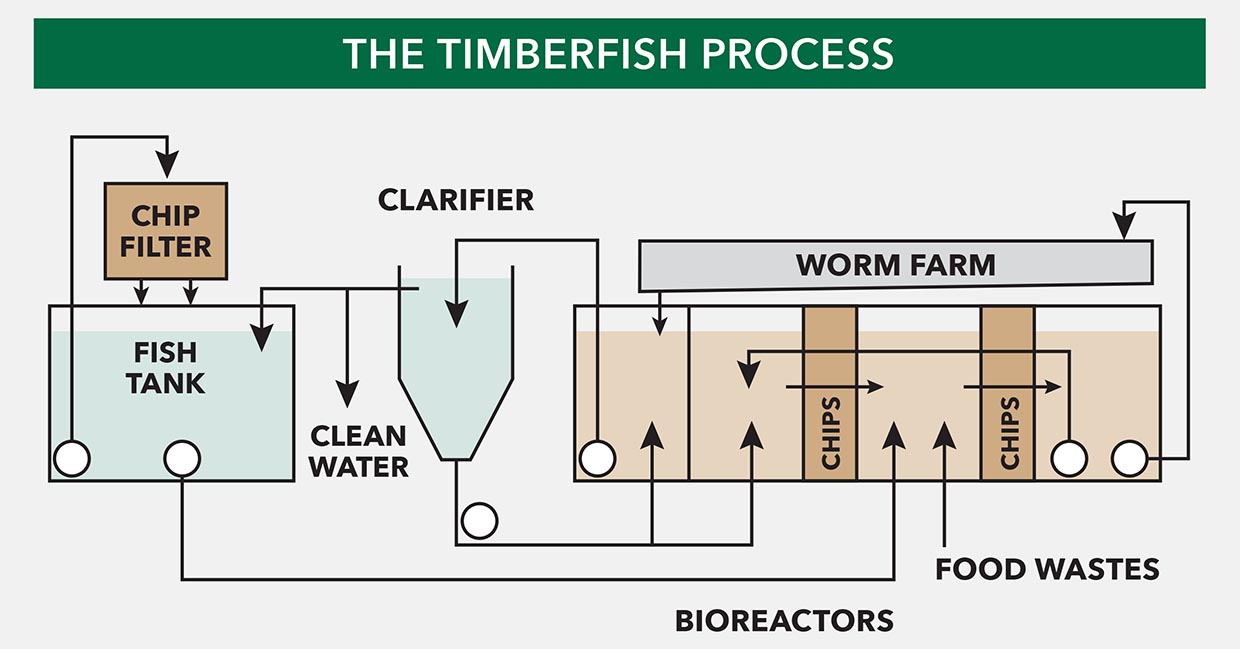

The Demo system itself is housed in a series of tanks, each being about 6 feet wide and 3 feet tall. It comprises several microbial growth bioreactors, a worm farm, a fish raising system, and an effluent treatment system that is derived from current activated sludge advanced wastewater treatment technology. The system contains a number of pumps, an aeration system, wood chip baskets, and a variety of piping and electrical components.

The system functions via a series of continually or periodically operating recycle flows. It can accept a periodic input of nutrients, such as food or aquaculture wastes, and discharges a tertiary treatment quality effluent. The system can operate with a long hydraulic detention time of 100 days or more. While having a location on a small farm associated with the university or a sewer connection is preferable the Demo can use periodic land application or truck its final effluent wastewater to a nearby municipal wastewater treatment plant. All of these options will be dependent on local and state regulations and permitting requirements. However, the extremely high quality of the effluent should make this a very manageable issue.

The following drawing presents a diagram of this demonstration system

The system functions as follows:

Bioreactor #1 Comprises five zones in the right hand side of a 1,000 gallon tank. This Bioreactor will receive the aquaculture wastes from the fish tank, and can receive small quantities of food or other nutrient waste from food and beverage production facilities, or even just solutions of ammonia or orthophosphate if desired. The bioreactor contains two netted chip basket zones and three water zones. A recycle pump maintains a continuous recycle flow and the bioreactor is vigorously aerated so that oxygen is continuously available to a large and diversified microbial population that is resident in the water and attached to the surfaces of the food and aquaculture wastes and wood chips. This promotes rapid microbial growth and consumption of the wastes.

As the microbial population increases a small fraction of the microbe rich water is periodically pumped into a Worm Farm. This Worm Farm comprises two or more shallow trays that contain a layer of wood chips. When the microbe rich effluent from Bioreactor #1 is pumped into the Worm Farm it flows through the trays and gradually seeps out of the Worm Farm. This action filters the stream thereby removing the suspended microbes which then become attached to the wood chips or settle around them making a soil like mixture. Worms living in the farm then eat the microbes and excrete worm castings which add to the soil like quality of the Worm Farm.

The effluent from the Worm Farm flows into the Bioreactor #2 (on the left hand side of the bioreactor tank). There additional aeration supports the growth of more microbes that degrade any non digested substrates from the worm farm. This biomass is then transferred to a clarifier in which floating or settling microbial solids are recycled back to Bioreactor #1. The clean water effluent from the clarifier is either discharged from the system as a final effluent or sent to the Fish Tank.

The Fish Tank is where the fish are grown. It is an aerated circular tank which has a basket containing wood chips perched directly above, but not touching, the water surface. A pump continuously pumps water to the top of the chip basket and this water then seeps down through the wood chips. Microbes living on the surfaces of the irrigated wood chips remove any soluble nutrients such as ammonia and phosphate from the fish wastes in the water.

A side stream from this pump is also directed into the tank itself in such a manner that it establishes a circular flow of water around the tank. This circular flow causes the solid fish wastes to be concentrated in the center of the fish tank. There a second pump periodically pumps these solids back into Bioreactor #1.

Periodically some worms are removed from the Worm Farm, separated from the chips and worm castings, and then fed to the fish. Once the concentration of worm castings in an area of the Worm Farm becomes too high the solids are removed from that area of the farm. The worms are harvested and the residual material separated into castings and wood chips. The castings can become a valuable potting soil and the chips can either be returned to the worm farm, returned to other chip zones in the system, or washed and used as a fuel source. Spent wood chips from the other baskets will also be similarly treated once 50 percent of their dry weight has been degraded by the microbes.

Depending on the rates of microbe, worm, and fish production a low protein fish pellet may be used as needed to supplement the fish feed from the system to maintain good fish growth. Such a pellet will not contain any fish meal or fish oil and hence will avoid any potential contamination from those sources. This would not impact the ability of the system to receive and process food wastes.

A full application of this system would only use microbial populations and worms and other invertebrates that are currently living in the local ecosystem. Fish would need to be obtained from a local or regional permitted fish hatchery and we will only grow fish that are native to, or well established in, a given local area.

The entire demonstration unit is skid mounted on a 34 foot long goose necked trailer with a 28 foot bed. Here is a photo of the demo system.

The system includes blowers, pumps, sensors, level controls, an electrical panel, process control instrumentation, phase converter if necessary, and internet connectivity. The trailer deck is 30 inches above ground level. It has sides that fold up for transporting and which can be lowered to provide decking around the system so that people can walk around and easily see all the components and moving parts. There are detachable railings to maintain safety on the deck. The system runs on three phase power so that we can operate variable speed pumps and blowers to provide adequate aeration, etc. It includes a phase converter to change a 220 v, 50 amp feed line to the appropriate three phase system. We can also run this system with a portable generator if necessary.

The system, with or without the trailer, could be located inside or outside depending on what was available. If the university wanted to keep the system it would probably be best if it were located inside. Alternatively, a small green house structure could be built to house the system. The system could take up to 20 to 30 gallons per day of brewery and/or restaurant waste and would then discharge 20 to 30 gallons of clean water back to the sewer, farm, or a holding tank for eventual land application or trucking to the wastewater treatment plant. The input loading would be dependent on the nitrogen and phosphorus content of the food waste.

The demo could produce 100 pounds of fish per year, more if additional tanks were added. This would depend on the strength and nutrient concentrations of the food wastes. For steady state operation the choice of fish species would depend on whether or not to heat or cool the fish tank. Catfish can tolerate both cold and warm water but grow best at about 76 F. Trout would do fine at 55 to 60 F but would die off above 70 F. If shrimp would be desirable then water temperatures need to be around 78 F. They don't do well under 70 and die by the time you get close to 60.

The Demo can be scaled up to a production level. TimberFish has operated a commercial pilot system at the Five & 20 Spirits & Brewing facility in Westfield, New York that would illustrate what this scale up might look like. This facility received all of the byproducts and production waste streams (no sanitary wastes) from the distillery and its companion brewery. The system grew fish and freshwater shrimp, recycled and treated all solid and dissolved wastes, produced a high energy wood chip residual which could be a renewable biofuel, and discharged a high quality effluent under strict permits issued by the New York State Department of Environmental Conservation.